| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : TAIGUO

Model Number : SZS

Certification : CE、EAC、SGS

Place of Origin : Henan, China

MOQ : 1

Price : US $16000.00

Payment Terms : L/C, T/T

Supply Ability : 100set

Delivery Time : 60 working days

Packaging Details : Bulk, packaged

Product type : Product Type Oil gas steam boiler

Structural form : Vertical type

Steam capacity : 6t/h-30t/h

Fuel : Oil、 gas

Applicable industry : Paper making, food processing, drying, textile, etc

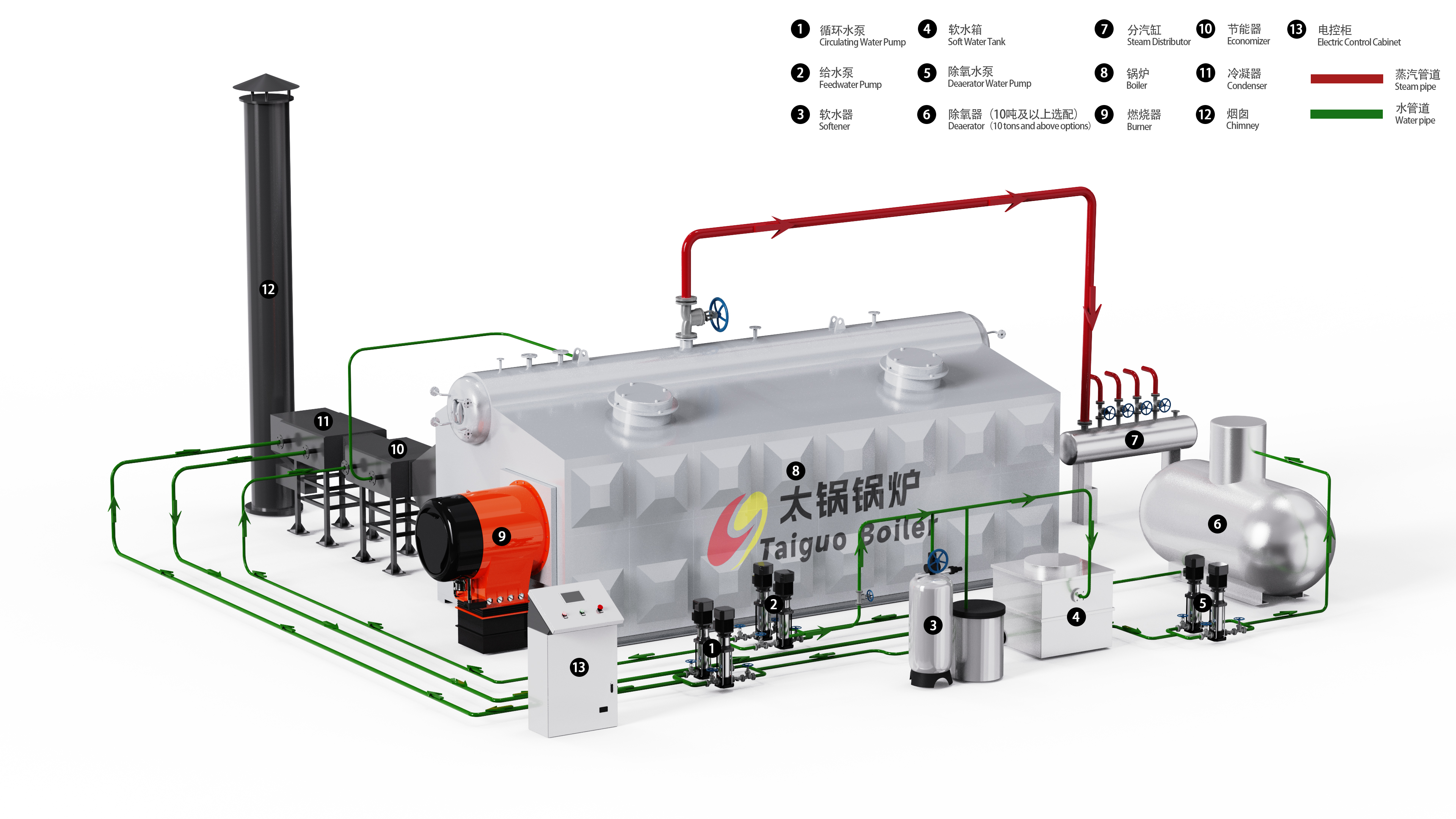

TAIGUO SZS series double barrel steam industrial boiler is a typical boiler barrel vertical "D" layout quick loading water tube boiler, micro-positive pressure operation. It is composed of an upper and lower pot tube, a film water cooling wall, superheater, convection tube bundle, energy saver and condenser, the burner is arranged in the front wall, the fuel is burned in the furnace, the flue gas successively washed the first convection tube bundle, superheater, second convection tube bundle, energy saver and condenser, discharged into the chimney.

(1) The boiler adopts double drum "D" type arrangement, compact structure, small footprint, good flame filling degree.

(2) The boiler is fixed at the front end and supported at the lower part. After ignition and heating, it can expand freely backward and upward, and the components work safely and reliably.

(3) The furnace water wall and convection flue are made of film wall structure, good air tightness, suitable for positive pressure operation, and effectively reduce the use of refractory materials and maintenance workload.

⑷ Self-supporting structure, good seismic performance. The weight of the body structure is placed on the steel base, and the membrane wall welded structure makes the whole boiler integrated, which is especially suitable for earthquake zones and earthquake fortified areas.

(5) The outer packing of the boiler adopts the pressing protection plate, which is beautiful and beautiful in appearance.

The furnace of the boiler is provided with an inspection hole, which provides great convenience for use and maintenance. Explosion-proof doors are provided on the top of the furnace.

SZS4 |

SZS6 |

SZS10 |

SZS15 |

SZ20 |

SZ25 |

SZS30 |

SZS35 |

SZS40 | ||

Rated evaporation (t/h) |

4 |

6 |

10 |

15 |

20 |

25 |

30 |

35 |

40 | |

Rated working pressure (Mpa) |

1.25/ 1.6/2.5 | |||||||||

Rate steam temperature (℃) |

194/204/226 | |||||||||

Feed water temperature (℃) | 20 | 20 | 104/20 | 104/20 | 104/20 | 104/20 | 104/20 | 104/20 | 104/20 | |

heating area(m) | Body | 90.22 | 125.6 | 205.56 | 216.84 | 271.5 | 285.24 | 392.34 | 457.7 | 523.12 |

| Economizer | 35.8 | 63.4 | 132.2 | 283.6 | 411.2 | 504.8 | 471.2 | 549.7 | 628.2 | |

| Condenser | 25.4 | 41.5 | 62.8 | 101.1 | 134.7 | 168.3 | 252.4 | 294.7 | 336.8 | |

| Available Fuel | natural gas ,biogas ,coke gas ,light oil ,methanol ,biodiesel etc ,heavy oil | |||||||||

Fuel consumption | Natural gas (Nm3/h) |

288 |

432 |

720 |

1080 |

1440 |

1800 |

2160 |

2525 |

2881 |

Light oil (kg/h) | 244 | 372 | 620 | 930 | 1240 | 1550 | 1860 | 2079 | 2373 | |

| Thermal efficiency (%) | >98 | |||||||||

| Weight biggest part of Transportation (t) | 25 | 32 | 40 | 45 | 50.6 | 60 | 68.2 | 77 | 85.5 | |

| Overall dimension boiler assembied L×W×H( m ) | 5.76*4.1 0*3.70 | 7.84*3.4 0*3.40 | 8.00*3.60*4.70 | 8.90*3.9 0*4.00 | 8.90*3.9 0*4.00 | 10.50*4. 12*4.15 | 10.50*4. 30*4.23 | 11.78*4. 40*4.35 | 12.82*4. 45*4.40 | |

|

|

Fuel Gas 30t/H Water Tube Steam Boiler Plc Control System Images |