| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : TAIGUO

Model Number : DZL

Certification : CE、EAC、SGS

Place of Origin : Henan, China

MOQ : 1

Price : US $5000.00-10000.00

Payment Terms : L/C, T/T, Western Union

Supply Ability : 100set

Delivery Time : 20-30 working days

Packaging Details : Bulk, packaged

Product name : Biomass boiler

Boiler type : Steam boiler

Rated evaporation capacity(t/h) : 1-15

Rated pressure(Mpa ) : 0 .7/ 1 .0/ 1 .25

Rated steam temperat ure( ℃ ) : 170/ 184/ 194

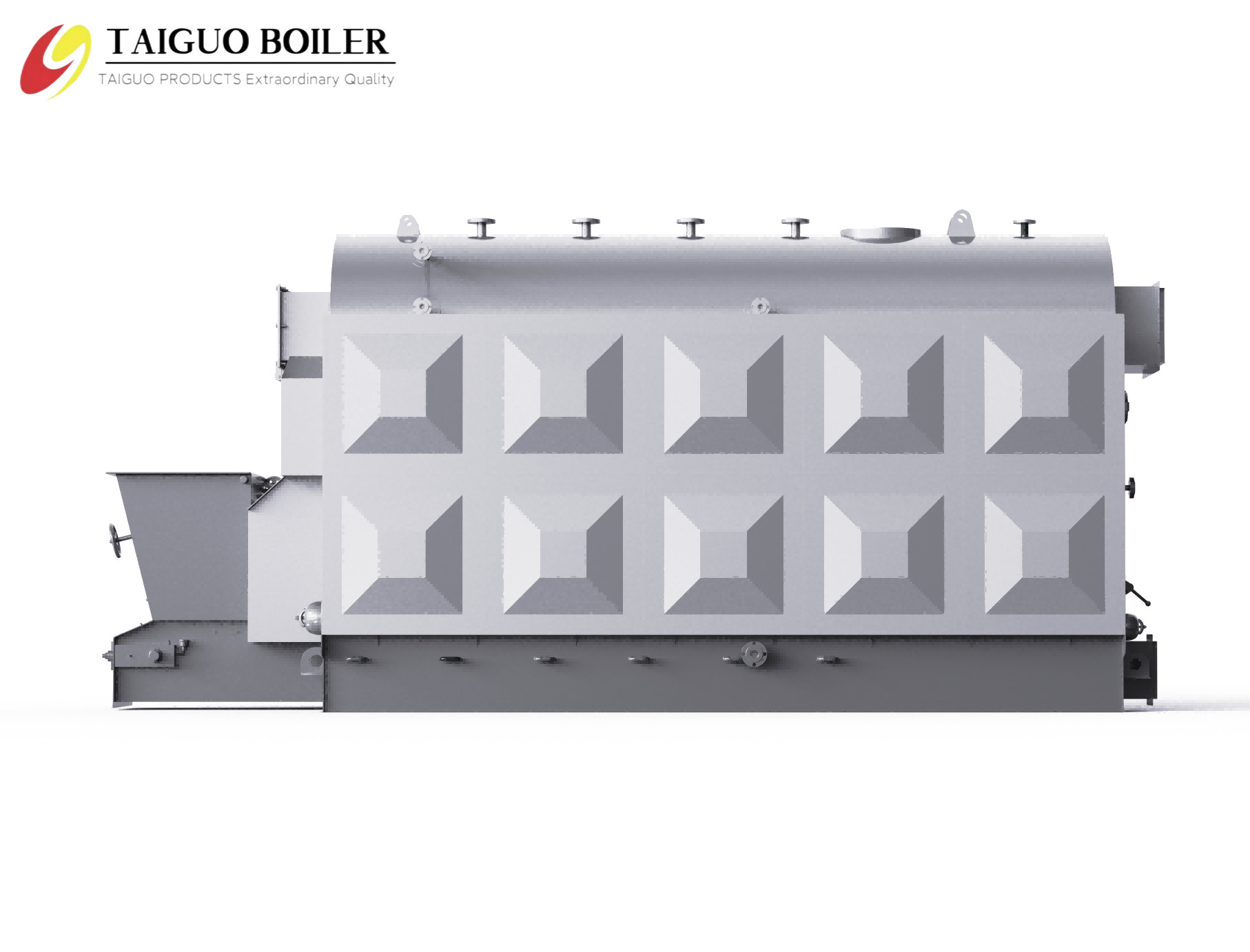

DZL series single-barrel longitudinal chain grate biomass boiler is a kind of horizontal three-return water-fire tube boiler, which is equipped with high efficiency heat transfer threaded smoke pipe, which can strengthen heat transfer effect and improve boiler thermal efficiency. DZL chain grate biomass boiler using lightweight small scale chain grate can feed uniform, easy control and more stable combustion. The design of the boiler is optimized, the problem of easy coking of the boiler is solved, the thermal efficiency is significantly improved, and the fuel cost is saved.

1. Single cylinder vertical arrangement, compact structure, small footprint, good flame filling degree.

2. The water wall adopts the light tube water wall, which is easy to manufacture and process.

3. The outer packaging protection plate adopts the pressed protection plate, which is beautiful in appearance.

4. The unique double-layer secondary air design improves the ignition conditions of biomass fuel, adopts an independent air chamber, and achieves reasonable air distribution, forming an aerodynamic field conducive to combustion in the furnace, making the combustion temperature high and combustion efficiency high.

| Model

item |

DZL1 |

DZL2 |

DZL3 |

DZL4 |

DZL6 |

DZL8 |

DZL10 |

DZL12 |

DZL15 | ||

| Rated evaporation capacity(t/h) | 1 | 2 | 3 | 4 | 6 | 8 | 10 | 12 | 15 | ||

| Rated pressure(Mpa ) | 0 .7/ 1 .0/ 1 .25 | 0 .7/ 1 .0/ 1 .25 | 0 .7/ 1 .0/ 1 .25 | 1 .25/ 1 .6 | 1 .25/ 1 .6 | 1 .25/ 1 .6 | 1 .25/ 1 .6 | 1 .25/ 1 .6 | 1 .25/ 1 .6 | ||

| Rated steam temperat ure( ℃ ) | 170/ 184/ 194 | 170/ 184/ 194 | 170/ 184 / 194 | 194/204 | 194/204 | 194/204 | 190/204 | 194/204 | 194/204 | ||

| Feed water temperat ure( ℃ ) | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | ||

| Heating Area( m) | Body | ~33 | ~50 | ~75 | ~100 | ~170 | ~200 | ~250 | ~340 | ~415 | |

| Economizer | 20 .7 | 25 .3 | 28 .6 | 33 . 12 | 87 .2 | 98 | 145 | 168 | 189 | ||

| Effective area of garte ( m) | 2 .22 | 4 . 1 | 5 .85 | 6.2 | 7 .95 | 9 .75 | 10 .77 | 13 .4 | 16 .6 | ||

| Fuel type | Biomass pellet,wood sawdust,bamboo chip,wood block,straw ,Jute, palm shell | ||||||||||

| Fuel Consumption (kg/h) | ~200 | ~400 | ~600 | ~800 | ~1000 | ~1200 | ~1400 | ~1600 | ~1800 | ||

| Flue gas temperat ure( ℃ ) | ~150 | ~150 | ~150 | ~150 | ~150 | ~150 | ~150 | ~150 | ~150 | ||

| T hemal efficiency(%) | ~82 | ~82 | ~82 | ~82 | ~82 | ~82 | ~82 | ~82 | ~82 | ||

| Weight of biggest part for t ransportation(t) | 17 | 18 .5 | 20 | 25 | 35 | 45 | 58 | 64 | 77 | ||

| Overall dimension of biggest part for t ransportation( m) | 5 . 1*2 .2 *3 | 5 .5*2 .3 *3 .3 | 6 .4*2 . 4*3 .5 | 6 .6*2 .6 *3 .6 | 8 . 1*2 .9 *3 .8 | 8 .3*3 . 1 *4 .0 | 8 .6*3 .2 *4 .2 | 9 .8*4 .2 *4 .5 | 12 .9*4 *7 .5 | ||

Q1: How can you get the best price quickly?

1.We need to know the boiler capacity, the fuel you plan to use and the steam pressure you need, and then we can confirm the boiler model.

2. Customer needs to provide us your name, email address and company name, and then we will send you price list immediately.And if you use whatsapp, skype or wechat, you can provide us your ID, it will be more convenient for our communication.

Q2:Why choose us?

1.40+ years of boiler manufacturing experience, 10 years of export experience.A grade boiler factory.

2.Free replacement of parts for one year, lifetime maintenance of the main engine, except for improper operation.

Q3: Details of electric control cabinet

Electric control cabinet adopts PLC touch screen, display in English. It shows working condition details of boiler, such as water temperature, water pressure, exhaust gas temperature, and over-pressure alarm, etc. In addition, the cabinet is used for set up the parameter, record and analyze the operation data, etc.

Q4:What is the using life of your boiler?

1.Normally the boiler is designed for 20 years life span, but with right operation and good maintenance,the boiler can be used for 20-25 years.

|

|

High Thermal Transfer Chain Grate Biomass Steam Boiler For Combustion Control Images |