| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : TAIGUO

Model Number : DZL

Place of Origin : Zhoukou in Henan Province

Certification : CE\EAC\SGS\ISO19001\ISO24001\ISO45001

MOQ : 1

Price : 8000

Packaging Details : To get ready,In bulk,

Delivery Time : Deliver the goods at the agreed time

Supply Ability : 100set

Type : Chain Grate Biomass Steam Boiler

Design Pressure : 1.0、1.25、1.6Mpa

Control System : PLC Intelligent Control System

Mode of transport : Land And Sea Transport

Fuel : Biomass Fuels, Such As Rice Husks, Straw, Wood Chips, Sawdust, Palm Husks, Coal, Etc.

Capacity : 1-20t/h

Application : Chemical Industry, Light Industry, Building Materials, Culture, Plastic Foam, Rubber Processing, Paper Making, Wood Processing, Clothing And Leather

Warranty Period : 12 Months

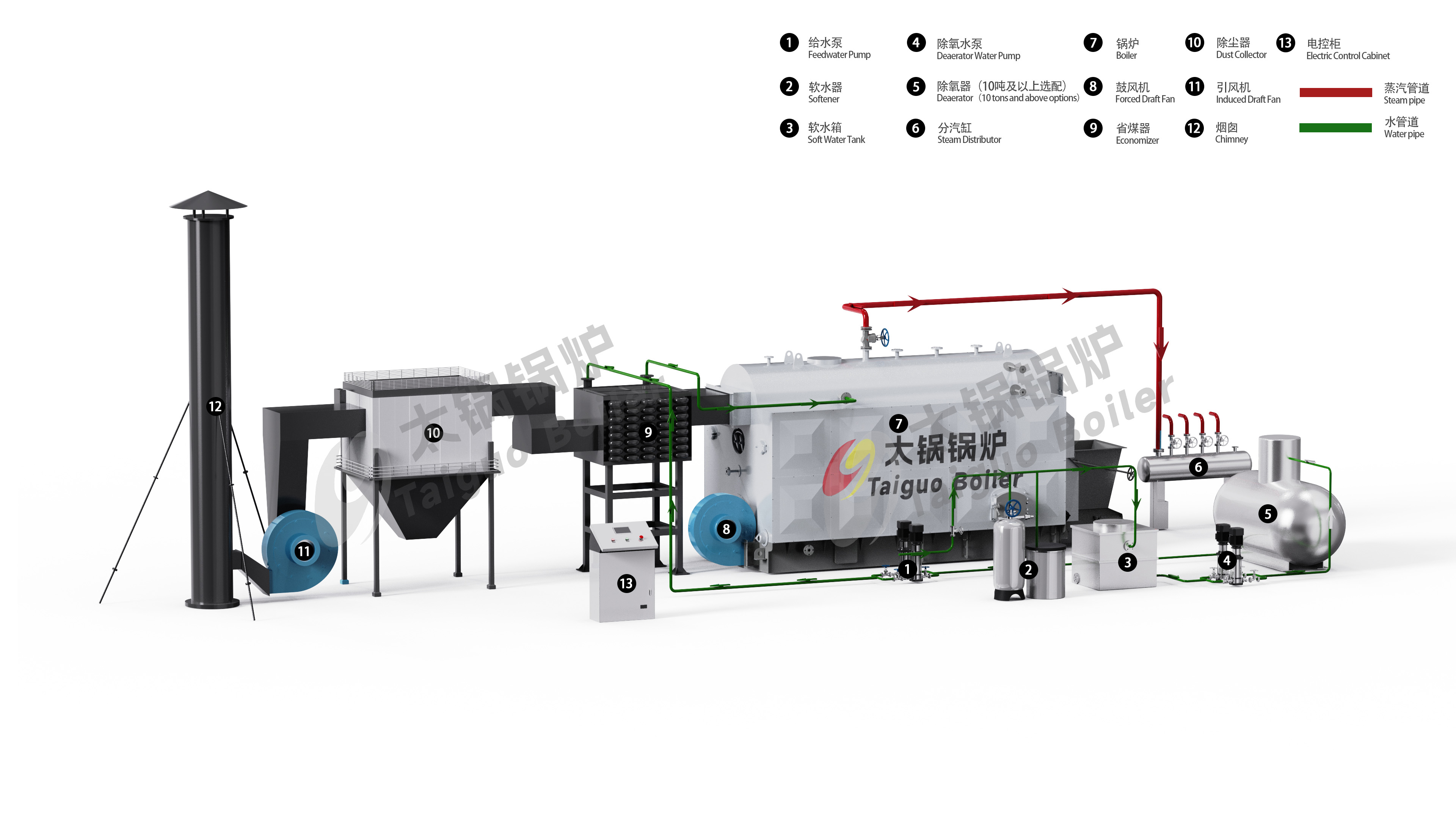

Chain Grate Biomass Steam Boiler is a kind of horizontal biomass steam boiler which is designed to use various types of biomass fuels such as rice husks, straw, wood chips, sawdust, palm husks, coal, etc. It can be transported by land and sea with design efficiency of more than 83%. This boiler is capable of providing steam of 1-20t/h with design temperature of 184,194,204℃. It is a reliable and efficient horizontal biomass steam boiler that meets the highest safety and quality standards.

1. The threaded smoke pipe is used to strengthen heat transfer, improve heat transfer coefficient and thermal efficiency, and adopt reasonable flue gas

The speed is conducive to the disturbance and erosion of smoke in the pipe, and the pipe will not accumulate ash and play the role of self-cleaning

2. Using fin film type water cooling wall, the boiler has small heat loss, good sealing performance and high thermal efficiency.

3. The cylinder is composed of arched tube plate and threaded smoke pipe, so that the cylinder changes from quasi-rigid to quasi-elastic structure, cancels the pulling member in the tube plate area and reduces the stress. The smoke pipe in the tube plate is changed from two return trips to one return trips, which solves the problem of tube plate cracks.

| name | argument |

|---|---|

| Structural Form | Horizontal |

| Design Temperature | 184℃, 194℃, 204℃ |

| Fuel | Biomass Fuels, Such As Rice Husks, Straw, Wood Chips, Sawdust, Palm Husks, Coal, Etc. |

| Capacity | 1-20t/h |

| Application | Chemical Industry, Light Industry, Building Materials, Culture, Plastic Foam, Rubber Processing, Paper Making, Wood Processing, Clothing And Leather |

| Design Pressure | 1.0Mpa, 1.25Mpa, 1.6Mpa |

| Mode of Transport | Land And Sea Transport |

| Type | Chain Grate Biomass Steam Boiler |

| Warranty Period | 12 Months |

| Design Efficiency | ≥83% |

Chain Grate Biomass Steam Boiler provides technical support and services to customers. Our team of experts is available to answer any questions you may have regarding the installation, operation, and maintenance of your steam boiler. We also provide regular maintenance services to keep your boiler running at optimum efficiency and reduce downtime. Additionally, our engineers are trained to troubleshoot any issues you may experience and provide detailed solutions to ensure your steam boiler is running smoothly.

Q1: How can you get the best price quickly?

1.We need to know the boiler capacity, the fuel you plan to use and the steam pressure you need, and then we can confirm the boiler model.

2. Customer needs to provide us your name, email address and company name, and then we will send you price list immediately.And if you use whatsapp, skype or wechat, you can provide us your ID, it will be more convenient for our communication.

Q2:Why choose us?

1.40+ years of boiler manufacturing experience, 10 years of export experience.A grade boiler factory.

2.Free replacement of parts for one year, lifetime maintenance of the main engine, except for improper operation.

Q3: Details of electric control cabinet

Electric control cabinet adopts PLC touch screen, display in English. It shows working condition details of boiler, such as water temperature, water pressure, exhaust gas temperature, and over-pressure alarm, etc. In addition, the cabinet is used for set up the parameter, record and analyze the operation data, etc.

Q4:What is the using life of your boiler?

1.Normally the boiler is designed for 20 years life span, but with right operation and good maintenance,the boiler can be used for 20-25 years.

|

|

Heat Transfer Chain Steam Boiler Mechanized Feed High Efficiency For Industrial Images |