| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : TAIGUO

Model Number : DZL

Certification : CE、EAC、SGS

Place of Origin : Henan, China

MOQ : 1

Price : US $10000.00

Payment Terms : L/C, T/T

Supply Ability : 100set

Delivery Time : 30 working days

Packaging Details : Bulk, packaged

Product name : steam heat boiler

Structural form : horizontal

Steam yield : 4t/h-10t/h

Mode of transport : Sea and land transport

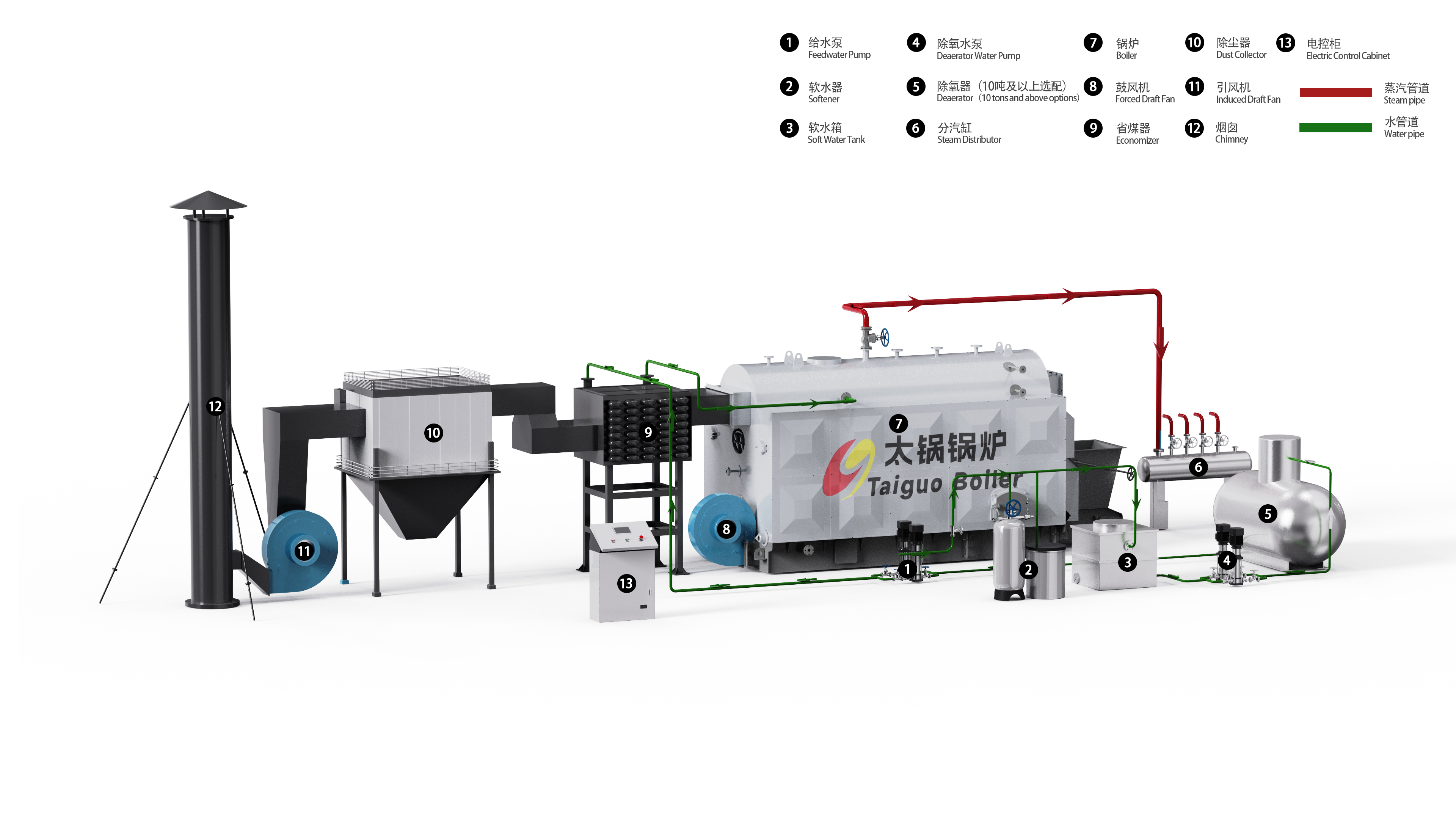

The biomass steam boiler is a single-barrel longitudinal water-fire tube shell type steam boiler, the combustion equipment is a chain grate, the left and right sides of the furnace are equipped with fin film type water cooling wall, the inside and outside of the furnace are tubular convection heating surface, and the threaded smoke pipe convection heating surface is arranged in the pot drum. The latest research on fin film type water wall, arch tube plate, thread smoke pipe, boiler shell bottom insulation, front and rear arch optimization, grate split bin air supply, etc., solved the boiler shell type boiler tube plate cracks, boiler drum bottom bulking, water wall burst pipe, low thermal efficiency, insufficient output, poor coal quality adaptability and other problems.

1. The front and back arches are optimized. The long and low back arches transport the flue gas to the higher front arches with the right upward inclination Angle of the front arches, and the flue gas forms α flame, which is conducive to the mixing and burning of the flue gas.

2. Thicker and reasonable furnace wall insulation design makes the boiler surface temperature within 50℃, reducing heat loss.

3. To improve coal ignition conditions. The independent air chamber is adopted to achieve reasonable and accurate air distribution and make the furnace

An aerodynamic field conducive to combustion is formed in the chamber, which not only improves combustion but also expands the adaptability of coal.

4. Using fin film type water wall, the boiler has small heat loss, good sealing performance and high thermal efficiency.

|

item |

DZL1 |

DZL2 |

DZL3 |

DZL4 |

DZL6 |

DZL8 |

DZL10 |

DZL12 |

DZL15 | ||

| Rated evaporation capacity(t/h) | 1 | 2 | 3 | 4 | 6 | 8 | 10 | 12 | 15 | ||

| Rated pressure(Mpa ) | 0 .7/ 1 .0/ 1 .25 | 0 .7/ 1 .0/ 1 .25 | 0 .7/ 1 .0/ 1 .25 | 1 .25/ 1 .6 | 1 .25/ 1 .6 | 1 .25/ 1 .6 | 1 .25/ 1 .6 | 1 .25/ 1 .6 | 1 .25/ 1 .6 | ||

| Rated steam temperat ure( ℃ ) | 170/ 184/ 194 | 170/ 184/ 194 | 170/ 184 / 194 | 194/204 | 194/204 | 194/204 | 190/204 | 194/204 | 194/204 | ||

| Feed water temperat ure( ℃ ) | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | ||

| Heating Area( m) | Body | ~33 | ~50 | ~75 | ~100 | ~170 | ~200 | ~250 | ~340 | ~415 | |

| Economizer | 20 .7 | 25 .3 | 28 .6 | 33 . 12 | 87 .2 | 98 | 145 | 168 | 189 | ||

| Effective area of garte ( m) | 2 .22 | 4 . 1 | 5 .85 | 6.2 | 7 .95 | 9 .75 | 10 .77 | 13 .4 | 16 .6 | ||

| Fuel type | Biomass pellet,wood sawdust,bamboo chip,wood block,straw ,Jute, palm shell | ||||||||||

| Fuel Consumption (kg/h) | ~200 | ~400 | ~600 | ~800 | ~1000 | ~1200 | ~1400 | ~1600 | ~1800 | ||

| Flue gas temperat ure( ℃ ) | ~150 | ~150 | ~150 | ~150 | ~150 | ~150 | ~150 | ~150 | ~150 | ||

| T hemal efficiency(%) | ~82 | ~82 | ~82 | ~82 | ~82 | ~82 | ~82 | ~82 | ~82 | ||

| Weight of biggest part for t ransportation(t) | 17 | 18 .5 | 20 | 25 | 35 | 45 | 58 | 64 | 77 | ||

| Overall dimension of biggest part for t ransportation( m) | 5 . 1*2 .2 *3 | 5 .5*2 .3 *3 .3 | 6 .4*2 . 4*3 .5 | 6 .6*2 .6 *3 .6 | 8 . 1*2 .9 *3 .8 | 8 .3*3 . 1 *4 .0 | 8 .6*3 .2 *4 .2 | 9 .8*4 .2 *4 .5 | 12 .9*4 *7 .5 | ||

Q1: How can you get the best price quickly?

1.We need to know the boiler capacity, the fuel you plan to use and the steam pressure you need, and then we can confirm the boiler model.

2. Customer needs to provide us your name, email address and company name, and then we will send you price list immediately.And if you use whatsapp, skype or wechat, you can provide us your ID, it will be more convenient for our communication.

Q2:Why choose us?

1.40+ years of boiler manufacturing experience, 10 years of export experience.A grade boiler factory.

2.Free replacement of parts for one year, lifetime maintenance of the main engine, except for improper operation.

Q3: Details of electric control cabinet

Electric control cabinet adopts PLC touch screen, display in English. It shows working condition details of boiler, such as water temperature, water pressure, exhaust gas temperature, and over-pressure alarm, etc. In addition, the cabinet is used for set up the parameter, record and analyze the operation data, etc.

Q4:What is the using life of your boiler?

1.Normally the boiler is designed for 20 years life span, but with right operation and good maintenance,the boiler can be used for 20-25 years.

|

|

Single steam heat boiler coal burning fully automatic efficiency Images |